Blog

How to Choose the Right Love Joy Coupling in Satara: Expert Tips from Hylo Transmission

Choosing the right Love Joy Coupling is crucial for ensuring smooth power transmission, reducing machine downtime, and improving overall industrial efficiency. Whether you’re part of Satara’s manufacturing, sugar, dairy, or heavy-engineering sector, selecting the correct coupling can significantly improve your machinery performance.

As a trusted supplier of Love Joy Coupling in Satara, Hylo Transmission brings you expert insights to help you make the best choice.

1. Understand Your Application Requirements

Before selecting a coupling, identify the basic requirements of your machine:

- Type of machinery

- Operating speed

- Torque requirements

- Shaft size and alignment needs

The more accurate your data, the better your coupling performance will be.

2. Check Shaft Misalignment Tolerance

Love Joy couplings are known for handling angular, parallel, and axial misalignments.

When buying:

- Identify the level of misalignment your machine usually experiences

- Choose a coupling size and design that can compensate without causing wear

Improper selection can lead to early failure.

3. Consider the Operating Environment

Satara Industries deals with different environmental conditions:

- High temperature

- Dusty surroundings

- Moisture or chemical exposure

Hylo Transmission offers Love Joy couplings designed to withstand harsh working conditions commonly found in Satara’s industrial zones.

4. Determine the Required Torque Rating

Torque is one of the most critical factors when selecting a coupling.

To ensure long-term reliability:

- Always select a coupling with a torque capacity slightly above your machine’s requirement

- Avoid under-rated couplings as they can lead to vibration, noise, and breakage

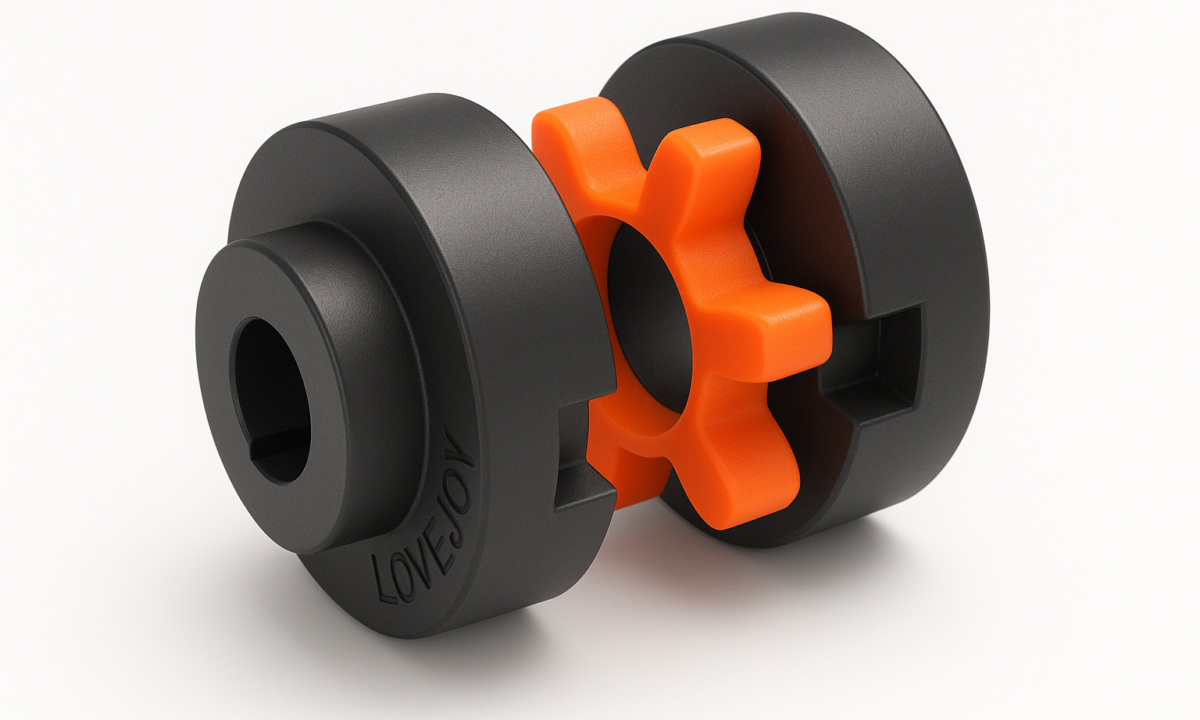

5. Evaluate Material and Build Quality

Love Joy couplings come in different materials:

- Cast iron

- Steel

- Aluminum

- Polyurethane spiders

For industrial setups in Satara, high-strength steel and premium spiders offer better durability and shock absorption.

6. Choose the Right Spider (Insert)

The spider plays a major role in performance.

Common options include:

- NBR (Rubber) – general-purpose, flexible

- Urethane – higher torque, longer life

- Hytrel – high rigidity, precise power transmission

- Bronze – extreme conditions

Hylo Transmission can help you choose the best insert depending on your application load and vibration levels.

7. Check for Maintenance Requirements

Low-maintenance couplings are ideal for industries running 24/7. Love Joy couplings are easy to:

- Install

- Inspect

- Replace

Choosing the right type ensures minimal downtime and longer operational life.

8. Consult Experts at Hylo Transmission

Selecting a coupling isn’t just about size—it’s about performance, environment, and machine condition.

Hylo Transmission provides:

- Technical guidance

- On-site inspection

- High-quality Love Joy Coupling in Satara

- Custom recommendations for your machinery

Conclusion

The right Lovejoy Coupling can enhance your machine’s efficiency, reduce breakdowns, and extend equipment life. By understanding torque, alignment, environment, and build quality, you can make an informed decision.

For the best Love Joy Coupling in Satara, trust Hylo Transmission — your reliable partner in advanced power transmission solutions.

FAQ’s

1. What is a Love Joy Coupling?

A Love Joy Coupling is a flexible shaft coupling used to transmit torque while managing misalignment between connected shafts.

2. Which industries in Satara use Love Joy Couplings?

Manufacturing, sugar mills, dairy processing, engineering units, packaging industries, and sectors utilizing power-driven machinery commonly use these couplings.

3. What are the benefits of using Love Joy Couplings?

They offer shock absorption, noise reduction, flexibility, easy installation, and misalignment compensation.